Technical & Field Services

We offer comprehensive support, including manufacturing process inspections, proposal process improvements, and competitive reviews. Our services extend to product development, substation and transformer engineering, design reviews, electrical, mechanical, structural, and seismic analysis. We also provide field and factory test witnessing, plant audits, design and manufacturing technology reviews, and quality assurance for both distribution and transmission electrical assets including power transformers, underground cables, Air and GIS switchgear, and overhead line equipment. Additionally, we assist with logistics, project management, standards certification, software development, and transformer design optimization. Our goal is to enhance efficiency and ensure the highest standards in transformer technology and service. Potencia Partners subject matter experts are capable of performing root cause failure analysis and investigations on LV, MV, and HV assets.

Transformer, GIS, HV Cables, Gas & Hydro Generators, Proposal Services

● Manufacturing process inspection

● Technical and commercial specification and proposal process improvement

● Developing test plans and procedures for FAT/SAT

● Proposal competitive review and OEM negotiations

● Product development services and support for OEM and service companies

Transformer Engineering

● Long-term pre-qualification and qualification cable testing (ITP design, witness, review)

● Design review for MV, HV underground, and submarine cables, including cable voltage rating, cable construction, conductor, insulation, fiber optic, semiconductors, metallic shield, armor, and jacket requirement

● Cable terminations and cable joints specification and tests (design, type, routine)

● Grounding and bonding specification and studies

● DTS, DAS, and PD monitoring systems

● Perform or witness cable commissioning tests, including AC Hipot & PD, TDR, OTDR

Overhead Line & Substation Engineering Services

● Design review of HV and MV overhead lines, and substation insulators & buses including audible noise, EMF, RIV, electric and magnetic field studies, stray & induced voltage studies

● Power system studies, including load forecast, load flow, short circuit, and arc flash studies

● Insulation coordination, and protection coordination studies

● Grounding studies and testing

● FAT and SAT witnesses for HV equipment such as HV insulators & surge arresters, overhead line hardware, overhead line conductors

Root Cause Failure Services

● 3rd party independent root cause failure investigation, testing, and analysis

● Onsite inspection, visual inspection, data collection and interview

● Work with accredited laboratories to perform material, chemical, mechanical, and electrical component testing

● Post-failure analysis to determine the root cause of failure of generation, transmission, and distribution assets

● Determine the “Mode of Failure,” “Apparent Cause,” and “Root Cause” of failures

● Identify potential causes and determine the most probable cause by evidence analysis

● Develop RCA ITP, questionnaires, procedures, and flowcharts for systematic RCA

Plant Audits & Recommendations

● Design and manufacturing technology review

● Suppliers and purchasing process

● Pricing and proposal process review

● Project management review

● Quality assurance review

● Logistics and field service

Product Certification & Homologation

● Standards certification for UL, IEC, IEEE, CSA

● Type test planning and witnessing recertification requirements

Software Implementation or Development

● HV assets, including transformer design optimization software

● CRM software configuration

● Project scheduling & management software configuration

Asset Management

● Fleet condition assessment for power utilities, renewable energy, oil & gas, and industrial plants & factories

● Health index and risk-based asset condition analysis

● Condition assessment of service-aged electrical equipment such as power cables, distribution transformers, overhead lines, and underground assets

● Asset analytics for critical infrastructure

● Develop a maintenance strategy to optimize your maintenance and repair costs and downtime while maintaining high reliability considering Reliability Centered Maintenance (RCM) development, reliability, availability, and maintainability analysis (RAM), and spare strategy optimization

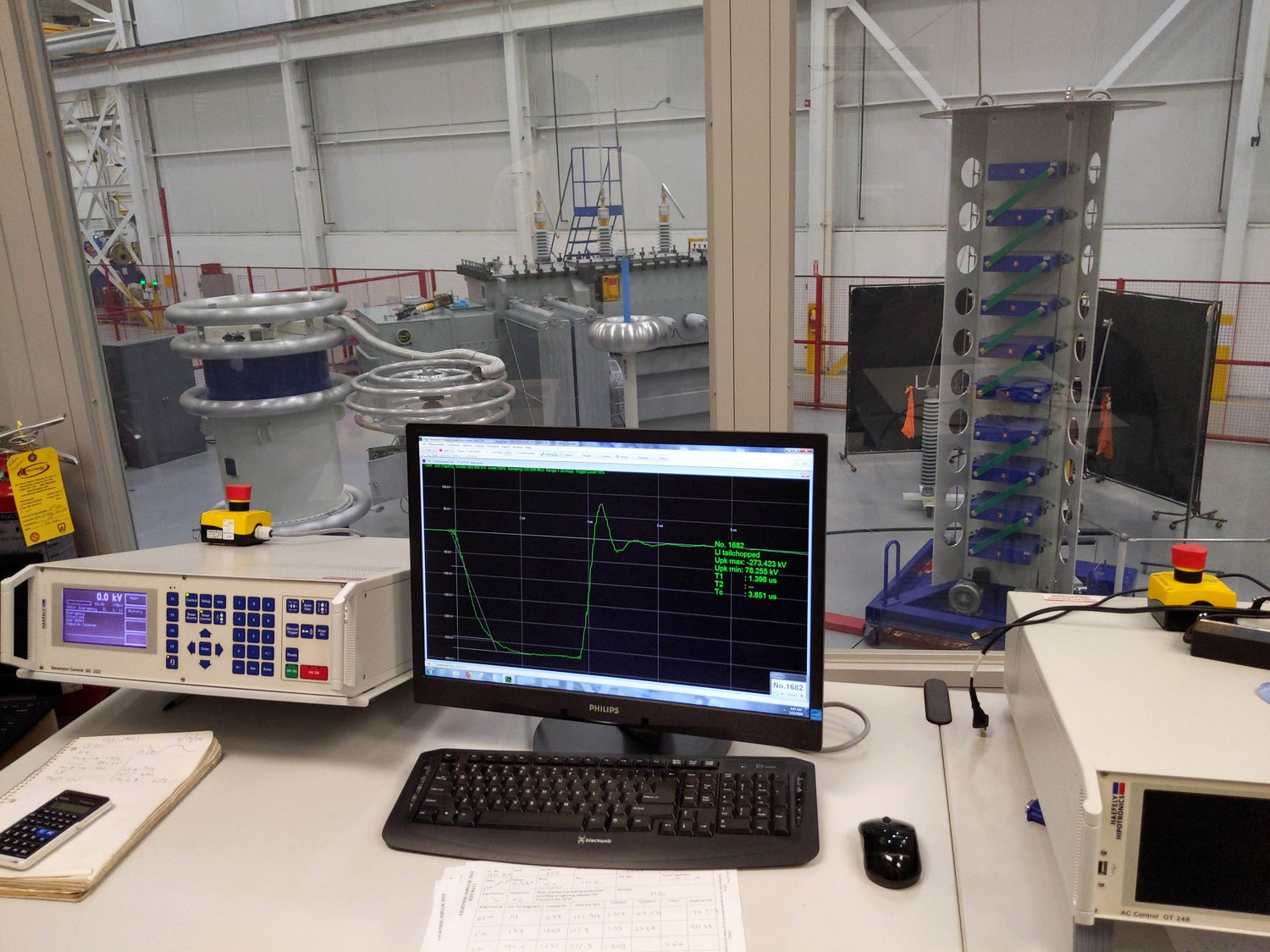

Test Bay and Laboratory Design & Setup

● Distribution and power transformer test bay design, layout, grounding, specification of equipment, test equipment supplier and purchasing process support, installation, and commissioning

● MV and HV cable testing setups, including type test and routine tests

● Upgrading AC Hipot, partial discharge, induced voltage, temperature-rise, load-cycling, impulse test, switching impulse test, and other high-voltage test setups

● HVAC and HVDC lab layout design, specification, and equipment support

Representative Projects

● Transformer FAT witness

● Transformer design review

● Onsite SAT commissioning of 30 MVA/50 MVA 230kV/13.8kV substation transformers, Missouri, 2024

● Transformer factory upgrades and expansion consulting, including machinery, equipment, test bay design, and suppliers and purchasing process for multiple factories in California and Texas, 2024-2025

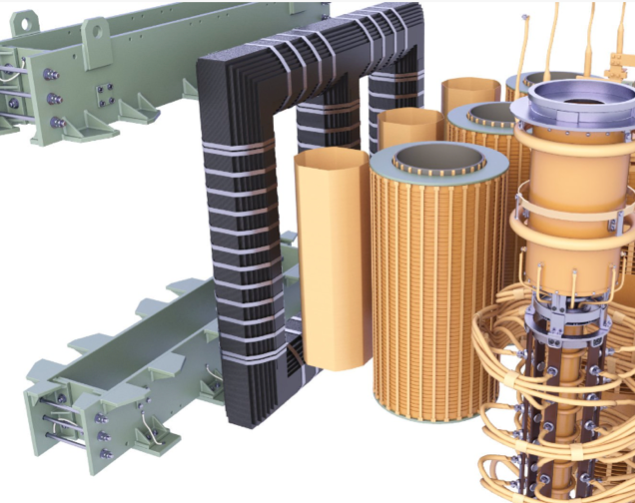

Active Part Revision

● Review AutoCAD files to identify construction and assembly issues.

● Use SolidWorks to model supports and detect connection problems.

● Assemble rack leads to check alignment and proper fit.

● Design and verify connection lines, measuring cable lengths and dielectric distances.

● Conduct full core and coil assembly reviews, ensuring correct positioning.

● 3D dielectric analysis with 1,150kV BIL and 15,000A current density.

● Fully assembled power transformer in a virtual model.

● Tank assembly revision services for improved quality control.